Plastic Formwork For Efficient Concrete Production

Introducing Our Advanced Plastic Formwork for Efficient Concrete Production

Product Description

Introducing Our Advanced Plastic Formwork for Efficient Concrete Production

Elevate your construction projects with our state-of-the-art Plastic Formwork System, meticulously designed to streamline the concrete pouring process while ensuring exceptional quality and durability. Our formwork offers an innovative solution that caters to the evolving needs of modern construction, making it an essential asset for any professional in the industry.

Specifications:

- Material: High-density polyethylene (HDPE)

- Panel Sizes: Available in customizable dimensions, standard sizes include 1200mm x 2400mm

- Thickness: 10mm for optimal strength and stability

- Weight: Lightweight design for easy handling, with each panel weighing only 20 kg

- Reusability: Up to 100 uses per panel, significantly reducing waste and cost

- Concrete Pressure Resistance: Can withstand pressures of up to 60 kN/m²

- Temperature Resistance: Effective in temperatures ranging from -20°C to 60°C

- Finishing: Smooth surface for superior concrete finish, reducing post-production sanding

Key Benefits:

- Cost-Effective: The extensive reusability of our plastic formwork drastically cuts down on material costs, offering unparalleled value over traditional wood or metal options.

- Lightweight and Easy to Handle: Our formwork is designed for optimal portability, allowing for quick setup and dismantling which leads to enhanced productivity on-site.

- Durability and Longevity: Crafted from high-density polyethylene, our formwork is resistant to moisture, chemicals, and wear, ensuring longevity and consistent performance in various environments.

- Perfect Finish: Achieve a smooth, high-quality concrete surface with minimal finishing required, saving you time and labor costs.

- Eco-Friendly Solution: By opting for our reusable formwork, you’re contributing to sustainable construction practices, reducing waste and promoting environmental responsibility.

- Versatile Applications: Ideal for a variety of construction projects including residential buildings, commercial properties, and infrastructure such as bridges and tunnels.

Unique Selling Points:

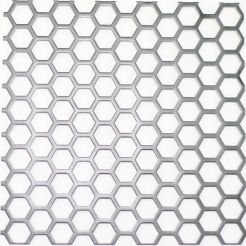

- Customizable Design: Tailor the formwork to your specific project needs with custom panel sizes and shapes, allowing for maximum versatility in design execution.

- Easy Assembly: Smart interlocking mechanisms make it simple to assemble and disassemble without the need for specialized tools.

- Weather Resistance: Unlike traditional formwork materials, our plastic panels perform excellently in various weather conditions, ensuring your projects progress without weather-related delays.

Customer-Centric Approach:

Understanding the challenges of concrete production, our Plastic Formwork System is engineered to meet the high standards of construction professionals. We are committed to ensuring that your projects are not just completed, but completed efficiently and economically. Our formwork combines innovative material technology with proven effectiveness, making it a trusted choice for builders who demand the best.

Conclusion:

Transform your concrete production process and experience the numerous advantages of our Plastic Formwork System. With its unbeatable combination of efficiency, cost savings, and environmental sustainability, it's the smart investment for future-ready construction.

Ready to elevate your construction projects? Contact us today to learn more about our Plastic Formwork and place your order!

Related Products:Plastic Formwork For Efficient Concrete Production, Plastic Formwork For Concrete Domes