Redispersible Polymer Powder - VAE-RDP

RDP is used as independent and additional adhesive in glue joints. For modification of dry building mixes on plaster and cement basis. Redispersible polymer powder on the basis of vinyl acetate polymer and vinyl ether , which has polyvinyl alcohol as protective colloid.

Product Description

Redispersible Polymer Powder (RDP) stands out as a pivotal adhesive agent in dry powder materials like cement and gypsum. It is the result of the spray drying of polymer emulsions, transforming them into a powder form through a series of processes such as high-temperature treatment, spray drying, and surface modification. When mixed with water, these powdered organic binders can re-disperse into a new emulsion, retaining properties similar to the original copolymer emulsion, forming a film after water evaporation.

Adding Redispersible Polymer Powder to mortar enhances its adhesion, bond strength, and flexibility. Firstly, it improves the mortar's water retention, forming a film that reduces water evaporation. Secondly, it enhances the bond strength of the mortar. Additionally, latex powder with hydrophobic properties can enhance the waterproofing performance of the mortar.

|

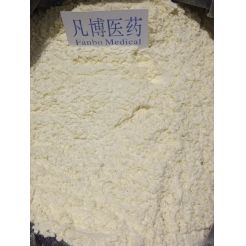

Appearance |

White or off-white powder |

|

Particle size |

80 |

|

Density g/cm³ |

500±100 |

|

Ash Content % |

12±2 |

|

PH ( 25-30℃) |

7-9 |

|

Residual moisture % |

≤2 |

|

Minimum film formation temperature |

4℃ |

Performance of Redispersible Polymer Powder in dry mortar:

Improved Adhesion: Enhances the adhesion of dry mortar to various substrates, ensuring weather-resistant bond strength under various conditions. For instance, it improves the bond strength between thermal insulation mortar and substrates such as EPS boards, EPS particles, concrete walls, and brick walls.

Increased Flexibility: Reduces the elastic modulus of materials, enhancing their elasticity and flexibility. The material can withstand substrate deformation, external impact, temperature variations, and freeze-thaw deformations. For example, Redispersible Polymer Powder significantly improves the dynamic crack resistance of putty and the heat aging resistance of tile adhesive, as well as the impact resistance of EPS board insulation systems.

Reduced Water Absorption: Lowers the water absorption rate of materials, with special hydrophobic latex powder yielding more pronounced effects. This minimizes damage caused by water to the formed mortar.

Enhanced Workability: Certain types of Redispersible Polymer Powder can improve the anti-sagging and flow properties of the mortar, enhancing its construction performance.

Application

● Gypsum / Cement / Mortar systems

● Movable/Regular mortar for thin coating

● Plaster boards / Gas-concrete block adhesives

● Wall/floor tile adhesive

● Open/closed-textured tile adhesive

● Plasters, fillers and finishing compounds

● Repair compounds for cracks filling and thin coating surface smoothing

● Repair compounds for finishing and leveling of concrete surfaces

● Polymeric alloys for grouting and cracks filling

● Water resistance / Grouting compounds

● Filling and embossing compounds

● Cement self-leveling flooring compounds

Advantage

● Dry strength / Durability / Lifetime increasing

● Mixture stability improving

● Water demand rate / bleeding reduction

● Air pore uniform distribution over volume

● Impact bending / Abrasive / Flexural strength increasing

● Temperature changes resistance

● Shrinkage reduction

● Adhesion/Cohesion increasing

● Stress cracking resistance increasing

● Provides high final strength

● Water retention improving

● Provides properties stability during different cements usage

As a leading manufacturer and supplier of RDP powder, we are committed to providing comprehensive information about this essential construction material. Should you have any inquiries regarding redispersible latex powder or seek a free quote, please do not hesitate to contact us. Our expertise in RDP empowers construction professionals to unlock the full potential of their building projects, ensuring durability, flexibility, and superior performance.

Packing & storage

Packed in 25 kg valved multilayer paper bags

Guaranteed shelf life in closed and undamaged package

It should be protected from sun and rain, fire, moisture, static electricity, open flame and sparks when transportation and storage.

What is Redispersible Polymer Powder (RDP)?

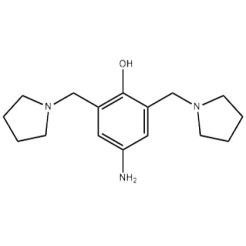

Redispersible Polymer Powder (RDP) stands as a versatile and crucial component in the construction industry, specifically formulated to elevate the performance of dry mortar mixtures. Derived from ethylene-vinyl acetate (EVA) polymer through a meticulous spray-drying process, RDP brings a myriad of benefits to building materials.

Performance Enhancement:

RDP is synergistically combined with cellulose ethers and various additives to enhance the properties of cement-based or gypsum-based mortars. This strategic combination results in a spectrum of improvements, including superior water retention, extended open time, enhanced workability, heightened adhesion to diverse substrates, and elevated performance metrics such as flexible strength and flexibility.

Technical Capabilities:

The technical prowess of RDP extends to bolstering cohesion, flexibility, and bonding strength. Its most pivotal contribution lies in imparting outstanding waterproofing performance. When applied to different substrates, RDP forms a thin film characterized by high tensile strength and adhesive properties.

Production Process:

The production of RDP involves the spray-drying of a latex emulsion, a process conducted under specific conditions. Polyvinyl alcohol is introduced during production to prevent the latex particles from agglomerating. The resulting polymer powders are often based on acrylic polymers, polyethylene vinyl acetate, ethylene vinyl acetate with tert-butyl carbonate vinyl acetate, or copolymers with vinyl acetate.

Key Components:

RDP is composed of polymer resins, serving as the cornerstone of dispersion particles. As additives, polymer powders play a dual role in modifying resins and polymer resins, thereby influencing the overall performance of the mixture.