What is Vacuum casting

What is Vacuum Casting?

Product Description

Product Description: Vacuum Casting – Your Ultimate Solution for Prototyping and Low-Volume Production

What is Vacuum Casting?

Vacuum casting is an advanced manufacturing technique that combines precision engineering with versatility. It is specifically designed for the creation of high-quality prototypes and low-volume production runs. Utilizing a vacuum chamber to eliminate air bubbles, this process ensures that your products are not only meticulously crafted but also exhibit superior finish and durability.

Key Specifications:

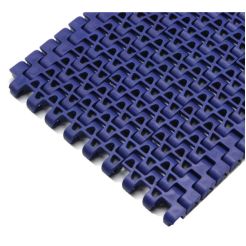

- Material Options: Polyurethane, silicone, and various thermoplastic elastomers.

- Casting Size: Parts up to 1 meter in length or various smaller components as required.

- Wall Thickness: Precision options ranging from 2mm to 5mm.

- Color Matching: Custom colors available to match your branding.

- Production Speed: Fast turnaround times of 5-10 days for prototype development.

- Surface Finish: Achieve a range of finishes from matte to high gloss.

Advantages of Vacuum Casting:

- High Accuracy: Experience impeccable detail and dimensional accuracy with our state-of-the-art vacuum casting technology.

- Cost-Effective: Ideal for low-volume production, vacuum casting reduces setup costs while maintaining quality.

- Versatility: This method allows for easy adjustments and modifications to your design, ensuring a perfect fit for your project needs.

- Rapid Prototyping: Speed up your product development cycle and bring your ideas to market faster.

- Material Diversity: Choose from a wide selection of materials that simulate various production-grade qualities for testing.

Functions and Applications:

Vacuum casting is versatile and can be utilized across various industries, including:

- Automotive: Create functional components for testing or short-run manufacturing, helping you validate your designs.

- Consumer Products: Perfect for prototypes of gadgets, appliances, and packaging designs that require realistic presentation.

- Medical Devices: Develop precise prototypes for product trials and FDA approvals, ensuring safety and compliance.

- Electronics: Produce intricate enclosures for electronic devices that require aesthetic appeal and functional integrity.

Why Choose Our Vacuum Casting Service?

Our vacuum casting service stands out from the competition due to our unwavering commitment to quality, speed, and customer satisfaction. We utilize the latest technology and experienced professionals to deliver products that exceed your expectations. From the moment you place your order, we work tirelessly to ensure a seamless experience, keeping you informed throughout the process.

Don’t Miss Out!

Transform your ideas into reality with vacuum casting. Enhance your prototyping and production capabilities today. Contact us for a free consultation, and let us help you discover how our vacuum casting solutions can drive innovation and elevate your projects. Your success is our priority!

Related Products:What is Vacuum casting, Custom Sheet Metal Fabrication Service